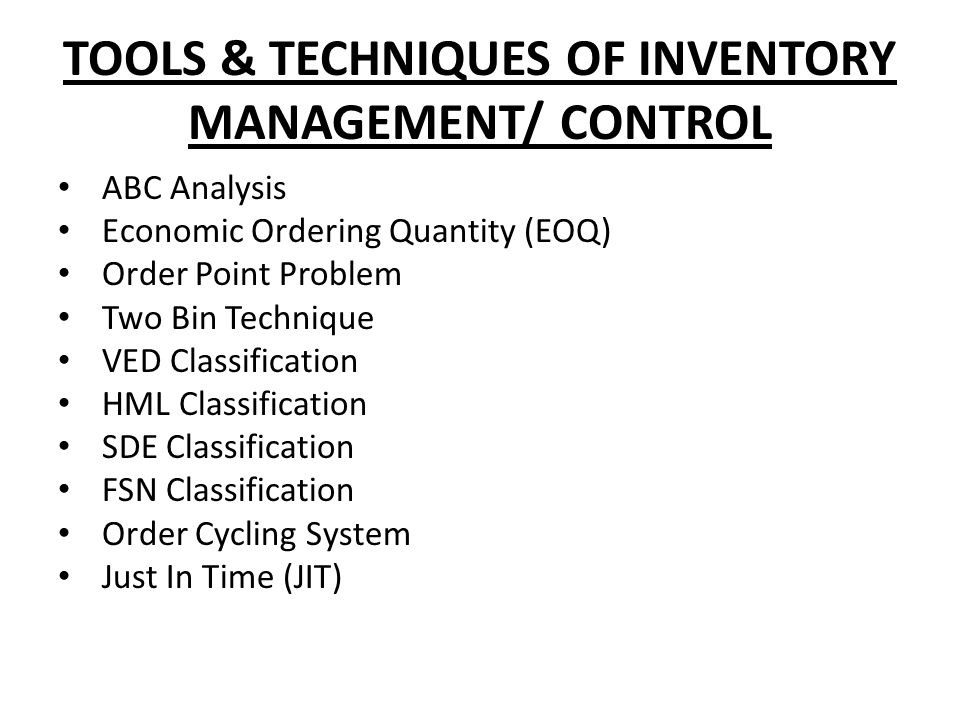

Inventory Management Techniques Ppt Free Download

INVENTORY MANAGEMENT ppt - Free download as Powerpoint Presentation (.ppt /.pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Prod 2100-2110 Inventory Control 0. Decision Systems for Inventory Management and. Techniques for lot sizing have already been proposed in the.

Question of fixing stock levels: Question of fixing stock levels Shriram enterprises manufactures a special product “ZED”. The following particulars collected for the year 2010:Monthly demand of ZED – 1000 UNITS Cost of placing an order rs. 100 annual carrying cost per unit rs. Vray Rhino Serial. 15Normal usages 50 units per weekMaximum usage 75 units per weekMinimum usage 25 units per week Re- order period 4 to 6 weeks compute from the above –1- Re –order quantity 2- Re-order level 3.

Minimum level4- Maximum level 5- average stock level. JUST IN TIME (JIT) INVENTORY SYSTEM: JUST IN TIME (JIT) INVENTORY SYSTEM just-in-time (JIT) is an inventory strategy that strives to improve a business's return on investment by reducing in-process inventory and associated carrying costs. To meet JIT objectives, the process relies on signals between different points in the process, which tell production when to make the next part. Are usually 'tickets' but can be simple visual signals, such as the presence or absence of a part on a shelf. Implemented correctly, JIT can improve a manufacturing organization's return on investment, quality, and efficiency.

Slide 31: Quick notice that stock depletion requires personnel to order new stock is critical to the inventory reduction at the center of JIT. This saves warehouse space and costs. However, the complete mechanism for making this work is often misunderstood.For instance, its effective application cannot be independent of other key components of a lean manufacturing system or it can '.end up with the opposite of the desired result.' In recent years manufacturers have continued to try to hone forecasting methods (such as applying a trailing 13 week average as a better predictor for JIT planning)[2], however some research demonstrates that basing JIT on the presumption of stability is inherently flawed.[3].

TWO BIN SYSTEM: TWO BIN SYSTEM Under this system, all inventory items are stored in two separate bins. In the first bins, a sufficient supply is kept to meet the current requirements over a designated period of time, in the second bin, a safety stock is maintained for use during lead time. When the stock of first bin is used, an order for further stock is immediately placed, the material in second bin is then consumed to meet stock need until the new product is received. Bored Aussie Installer Gta. On receipt of new order, second bin is restored and the balance is put in the first bin.